Services

We offer

Model-Based Engineering Implementation

We assist organizations in transitioning to a model-based engineering (MBE) approach, incorporating model-based definition (MBD) and other model based principles for end-to-end digital continuity.

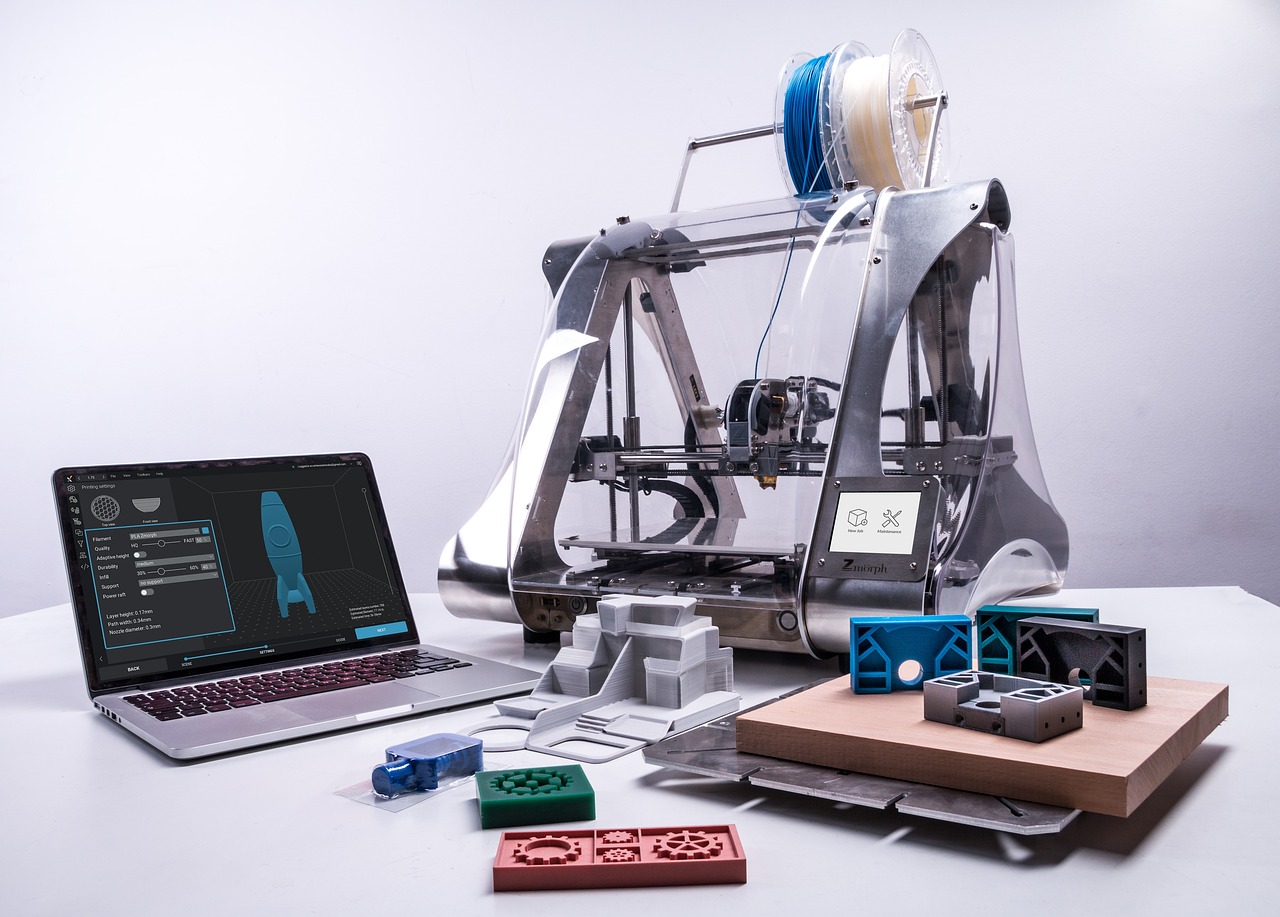

Advanced Manufacturing and Prototyping

Provide specialized Manufacturing and prototyping services to tackle the most complex challenges, from designing intricate components to developing 3D Printing and Additive manufacturing processes.

Custom CAD/CAM Tools

Design and implement custom CAD/CAM tools tailored to your specific needs, ensuring your workflows are optimized for maximum productivity and accuracy.

Model Based Engineering Implementation

- MBSE Implementation: Building digital threads that unify system design and requirements.

- MBD Integration: Embedding PMI directly into 3D CAD models for 2D-less manufacturing.

- Digital Twin Enablement: Establishing digital twins to improve simulation, testing, and validation.

- Standards Validation and Compliance: Ensuring adherence to industry standards such as ASME Y14.41.

Advanced Manufacturing and Prototyping

-

Additive Manufacturing Integration: Leveraging 3D printing and additive for fast and accurate production.

-

Advanced CAD Design: Creating intricate components, assemblies, and systems with precision.

-

Advanced Design for Manufacturing (DFM): Ensuring designs are optimized for advanced production methods.

-

Rapid Prototyping Optimization: Streamlining design-to-prototype workflows and reducing iteration cycles.

Custom CAD/CAM Tools

-

Custom Automation: Streamlining repetitive design tasks to save time

-

Feature Enhancements: Modifying software features for unique industry requirements.

-

CAD/CAM Integration: Seamlessly linking CAD designs to CAM tools for efficient manufacturing transitions.

-

Consultation and Support: Ongoing guidance to ensure tools align with your evolving needs.